Introduction

- Warning Assembly of a Electric Vehicle charging station requires wiring Alternating Current (AC) components that will be exposed to voltages from 100 to 250v. If you do not have the experience and knowledge required to safely work with AC voltages please consult with an experienced electrician for assistance and inspection of your work.

- Note Regularly inspect your charging station. Pay special attention to excess heat, components, handles, and wiring will be warm but they should not be HOT...

- Always Disconnect your charging station from power before performing an inspection and/or maintenance

Kit Contents:

1 - Enclosure

1 - Metal Plate

1 - Screw Pack Enclosure Lid

1 - Screw Pack

1 - LCD Seal Kit

1 - Push button

1 - Relay

3 - Red Wires

3 - Black Wires

1 - Ground Bar

2 - Cable Glands Small

1 - OpenEVSE v4 Controller

1 - RGB Liquid Crystal Display

1 - Wifi Kit

Tools

Parts

No parts specified.

-

-

Place the 4 - 10mm M2.5 screws through the top of the enclosure.

-

Flip lid upside down and stack... Foam window seal, then LCD clear window (remove Protective coating from both sides) .

-

Note: Kits shipped before February 2018 also include a LCD brace. Install the brace on top of the LCD window.

-

Kits shipped February 2018 and later include a 1/4" thick LCD window and do not require the brace.

-

Place the 4 - 10mm M2.5 screw through the lid. Compress window foam and thread into the 4- Hex Standoffs. Tighten each one hand tight compressing the foam fully.

-

-

-

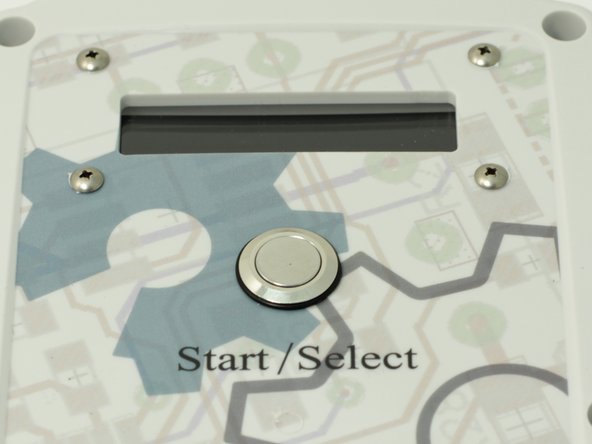

Mount the water resistant button switch to the enclosure lid, O-ring seal on the outside. Do not over tighten seal, if squeezes out of place the button is too tight.

-

Test enclosure lid for water tightness. Spray water around the LCD window and button and ensure water does nor leak to the back side of the lid. Adjust as necessary.

-

Using 4 - 6mm M2.5 screws. Mount LCD module to the lid.

-

Screws should be secure. Take care not to over tighten.

-

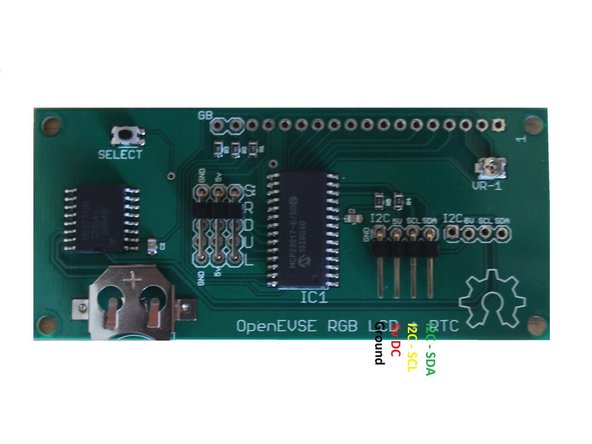

Connect 4 pin connector to LCD note the color that represents Ground (Green as pictured). Ground pin is labeled (pin closest to board center).

-

Optional - If installing Wifi, now is a good time to mount. Position to the left of the button with the header pins to the far left.

-

Optional - Insert a CR1220 or CR1225 coin cell into the battery holder. If using charging station timers this will keep time during power outages.

-

-

-

If your kit contains a Packard C240C contactor, continue here. Guide

-

Mount hex standoffs to the top side of the plate mounting plate with 4 - 6 mm M2.5 screws. Mount the OpenEVSE board to the hex standoffs with the other 4 - 6mm M2.5 screws.

-

Mount Ground bar header block to the mounting plate from the top using 2 - 5/8" self threading screws.

-

Do not over tighten the self threading screws. tighten until secure. Use of a non powered Screw driver is recommended.

-

Mount the Struthers - Dunn contactor using 2 - 1/2" self threading screws.

-

-

-

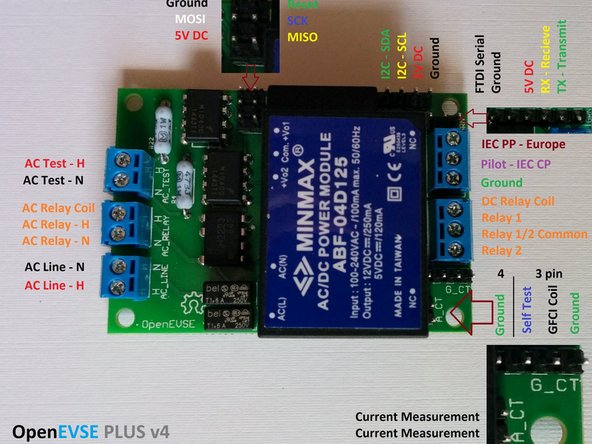

Review the connection diagram for the board you received in your kit. This guide depicts the latest board OpenEVSE v4.

-

-

Connections are slightly different between board versions. Refer to these diagrams if the image in this guide does not match your board version.

-

-

-

If your kit contains a Packard C240C contactor, continue here. Guide

-

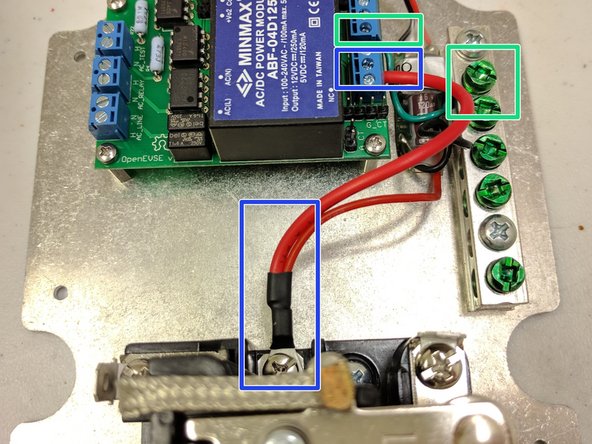

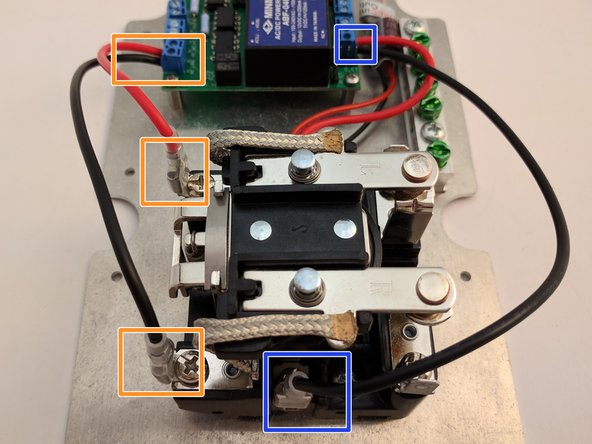

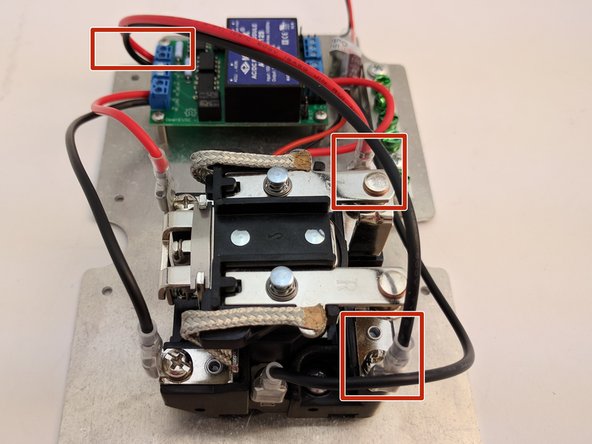

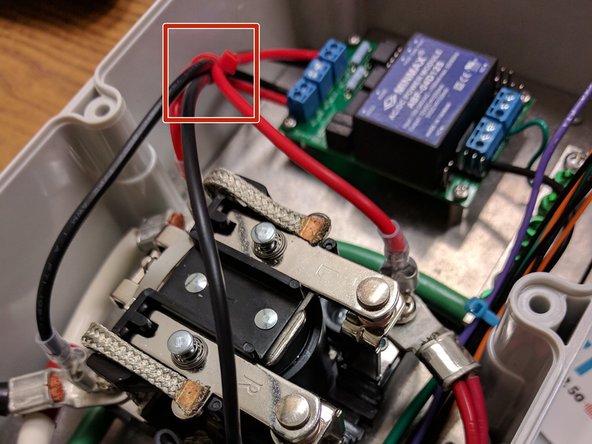

Struthers & Dunn - Connect DC relay coil (top) with a red wire to OpenEVSE controller Relay 1/2 Common. Connect relay coil (bottom) with a black wire to Relay 2.

-

Connect the +RED wire of the UBEC supply to DC_Relay 1/2 Common of the DC_Relay block or the +12V ring terminal of the relay.

-

Connect the -BLACK wire of the UBEC supply to the Ground bar.

-

Connect OpenEVSE AC_Line to the incoming AC side of the contactor.

-

Connect OpenEVSE AC_Test to the hot line of the contactor output (J1772 side) to both Hot 1 and Hot 2/Neutral.

-

Connect the Ground wire from the ground block to the OpenEVSE board.

Bob thanks for your clarification on the Blue Dot instruction. I guess I am to assume the Red wire is going to the “relay 1/2 common”? The author’s instructions are vague or inaccurate at times and the photos are at times useless or misleading. Could there not have been a few more photos showing clearly where the wires are going?

The instructions at blue dot say to connect the black wire to “pin 1”. I assume you meant pin one of the relay block. But the picture shows it connecting to pin two of the relay block. The mention of pins is misleading, there are no pins on the relay block. As per the diagram there is only relay 1, relay 1/2 common, and relay 2. The instructions should be amended to say the black wire connects to relay 2 of the relay block, not pin1.

A top down photo would really help here!

My kit arrived with no red leads. So I’m making them myself. But dressing these leads is difficult given the poor angles of these photos.

Cliff Stoll - Resolved on Release Reply

1. ++ on the value of perfectly vertical pics of the board so the wire locations are clear & not affected by parallax.

2. A lot neater if you cut the three red spade lug wires about 2” shorter since they all go to the near side of the contactor.

3. Ground wire was black and unstripped in my kit. (Green dot instruction)

4. Don’t attach the ring spade lugs to the contactor yet, just plug them into the wires, screw them down after connecting the J1772 (step 9) and the power cord (step 10). Otherwise you will just take the screws out after you have just put them in with the ring connectors.

Does anybody have a clean straight-down picture showing which wires go where in the controller board? The pictures here merely show wires going somewhere into the side of the controller board and are obscured by rectangles drawn onto the image. I read the text instructions but it leaves a lot of room for interpretation. If the pictures were better it wouldn’t be necessary to even have text in the instructions. Also, I see a shrink wrapped component laying on the mounting plate and next to the ground block but the instructions don’t even mention it. I am disappointed in the clarity of these instructions.

nathan steele - Resolved on Release Reply

I wound up soldering and crimping the ring terminal to both the thicker red wire and the UBEC power supply cable as you showed yours in the picture. I dressed it with some shrink tubing. Seems to look ok.

Andrew Halperin - Resolved on Release Reply

The first picture shows a connection with a wire that doesn’t exist in the kit I received. Or is the extra ring lug that is included intended to be used here?

Andrew Halperin - Resolved on Release Reply

The thicker wire is one of the three red wires with 1/4 QC terminals pre-crimped. The thin wire goes to the UBEC power supply for WiFi. The ring terminal can be used at the end of the UBEC red wire.

None of the AC connections are polarity sensitive. AC_Test are identical circuits. Just ensure the AC_Line wires connect to the AC Input and AC_Test connects to the load side of the relay.

I personally build with black wires across the bottom of the relay and reds across the top. Same on the board connector blocks black wires on the bottom red above. But again neither is polarity sensitive.

Christopher Howell - Resolved on Release Reply

Could you take a close up of the polarity of the AC Line and AC test connections in step 5 please? The third picture looks misleading, the hot and neutral inputs swap positions on the board, but the connectors look like they are in the same orientation. Step 8 seems to have a better view, but I think a close up of the board with everything connected would be best.

N Fettinger - Resolved on Release Reply

-

-

-

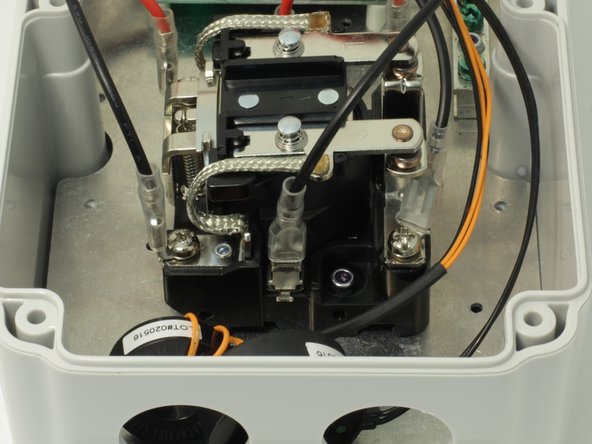

Install Cable glands on the enclosure.

-

Optional - If using a large input cable/gland install input cable (LEFT), use a drill with a step bit to enlarge the hole.

-

Mount plate to Enclosure box using 6 - self tapping screws (2 top, 2 middle 2 bottom).

-

-

-

Insert the J1772 cable through a Cable Gland and assemble loosely into the RIGHT hole in the box.

-

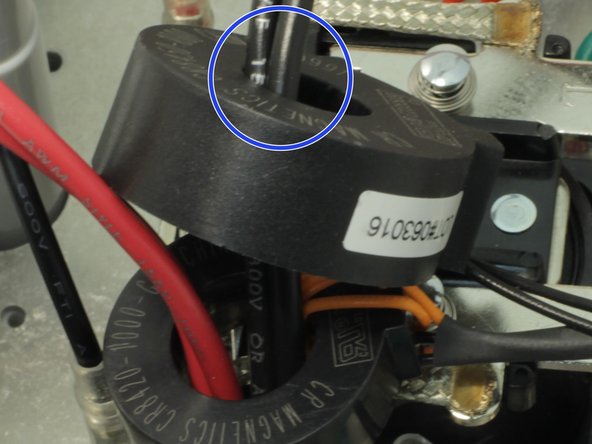

Thread BOTH AC lines through the Ground Fault Coil (4-pin). If you are using the OpenEVSE 40A J1772 Cable, this is both the red pairs AND the black pairs.

-

Thread one AC line through the current-measurement CT (2-pin OpenEVSE Current CT) . If you are using the OpenEVSE 40A J1772 Cable, this is either the red pair OR the black pair of wires.

-

The Ground should be connected with some extra slack so if the cable is forcefully pulled the pilot disconnects first and ground last.

-

-

-

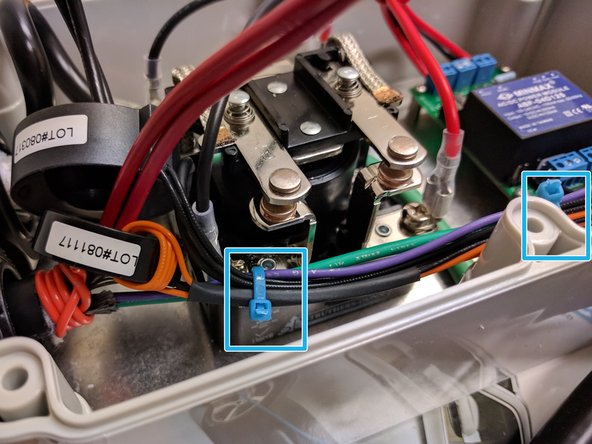

Organize the low voltage wires (EV Ground, EV Pilot, GFCI coil lead, Current coil lead and the relay coil) and secure with a tie wraps with light tension. Tuck the wires down to the bottom of the enclosure.

-

Connect the 4-pin GFCI CT connector to the OpenEVSE board. This coil has two black wires and two orange self-test wires looped through the coil with a 4 pin connector. Orange Self test wires positioned to the inside Black GFCI CT wires to the outside.

-

Connect the current measurement CT to the 2 pin connector (either direction is fine).

-

Connect the control pilot (CP) line (see below for common colors) to the OpenEVSE pilot screw terminal connection.

-

OpenEVSE Quick Charge Power and Tesla PURPLE, Leviton ORANGE, Yazaki BLUE

-

Use a tie wrap to secure the high-voltage low-current wires with light tension. Position so that the wires are pulled away from the center screw post/seal.

-

-

-

OpenEVSE Ultra Flexible Cable include factory terminated ends with Ring Terminals. Other cables will require 6AWG terminals to be crimped following the recommendations of the terminal supplier.

-

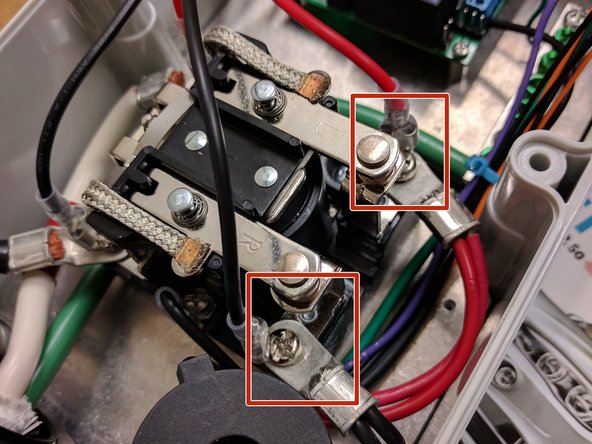

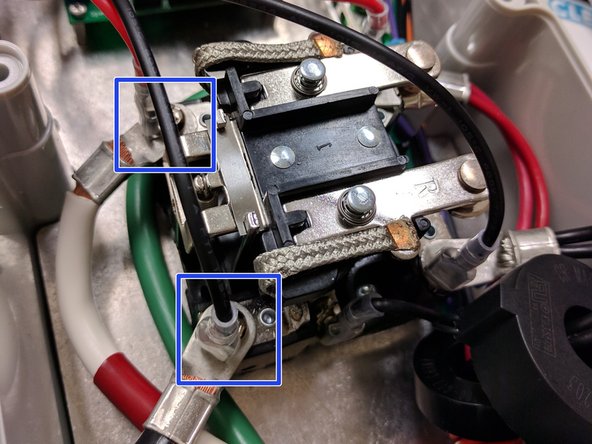

Screw the Power Terminals to the relay with the Quick connect terminal for OpenEVSE AC_Test on top.

-

Tighten the J1772 cable gland and check its integrity.

-

-

-

Insert the AC Input cable through the LEFT Cable Gland and assemble loosely into the hole in the box.

-

Check the color code for your country and plug type as it varies region by region. Pictures show US 3 wire (Green, White, Black). Note US 4 wire (Green, White, Black, Red) White Neutral not used and should be capped.

-

Run the Ground wire along the bottom of the enclosure and secure the conductor the the ground block.

-

Screw Ring Terminals to the contactor with the Quick connect terminal for OpenEVSE AC_Line on top.

-

Tighten the cable gland and check its integrity. Check the input wires are secure.

Ok now I’m confused, as stated in the picture it is using white, black, green three wire? It looks like you’re using the white as a hot to get level 2. That’s not code. Was the picture for level 1?

The picture is 3 wire hot hot ground. The white wire had 1 inch or red shrink wrap to indicate it is hot 2.

-

-

-

Connect the LCD cable to the OpenEVSE controller. The pin closest to the board edge is ground (green pictured).

-

-

-

Power ON. Use caution.

-

A OpenEVSE programmer can be used to power the controller to adjust contrast. Note there will be errors (this is normal) as not all systems are powered.

-

Adjust LED contrast (VR-1) if text is not visible. Be very careful not to touch any while powered.

-

When adjusting, be gentle. Do not force past the stop in either direction. If forced past the stop, the part will no longer function.

-

Secure the enclosure lid. Tighten the screws slowly alternating across and top, middle and bottom.

-

-

-

To Enter the Menu Press and hold the button (long press). Press and release (short press) to scroll through Options.

-

Set Current to desired Value (80% of your circuit breaker value). Menu => Setup => Max Current.

-

Enable GFCI Self Test. Menu => Setup => GFI Self Test

-

Cancel: I did not complete this guide.

7 other people completed this guide.

7 Comments

Where are the instructions for the WiFi wiring? Step 2 shows a location for the board, and Step 5 shows connection of the UBEC power supply which I assumes powers the board. How do you connect the power cable to the WiFi board and how do you connect a ?data? cable to the OpenEVSE board?

For 120 V use, I built an adapter cable with a 30A "dryer" cable from Menards, and a 14-50R Camco receptacle I bought online, following the above instructions. Hhalf the cost of buying this assembly pre-built is pretty sweet. Works like a charm on both 120V & 240V! It is very nice to have the dual voltage versatility when travelling. Thanks for the details, Chris.

Can you provide specific details, or perhaps an Add-On Guide section, on how the Deluxe Level1/Level2 50Amp EVSE unit is to be connected to a regular 120V outlet (to provide Level 1 power)? The user probably needs to set a much lower current limit in the menu (How much?) and to plug it in, do we need to build a conversion cable from the regular 120V plug to a NEMA 14-50 socket? In that case, how to connect the 3 pins of the regular plug to the big 4-pin socket? Does this require that we use the previously discarded Neutral (white) wire in the big 4-wire cable that enters the EVSE enclosure (if so: how?)?

Lourens Broekhuizen - Resolved on Release Reply

The NEMA 14-50 plug is connected Hot 1, Hot 2 and Ground. For 120v you will need to build an adapter that is wired Hot 1, Hot 2, ground on the 14-50 (neutral is not connected) socket to Hot 1, Neutral, ground on the 120v plug.

OpenEVSE will automatically detect just one hot and set the current to 12A. L1 and L2 current is saved independently.

I have a February 2018 kit (shipped Feb 2, 2018) and it includes the LCD brace and foam washers. The screw heads are a different style than pictured and are basically incompatible with the foam washers (the heads are too small).

The foam doesn’t compress much in the center (long axis) even with the brace. I’m tempted to put a bead of silicone around the window.

Nick - Resolved on Release Reply

Apparently the sealing washers are not required with the 1/4” thick LCD window and are not included after Feb 2018.

TimT - Resolved on Release Reply